New Approach Could Make Reusing Captured Carbon Far Cheaper, Less Energy-Intensive

Apr 25, 2024 — Atlanta, GA

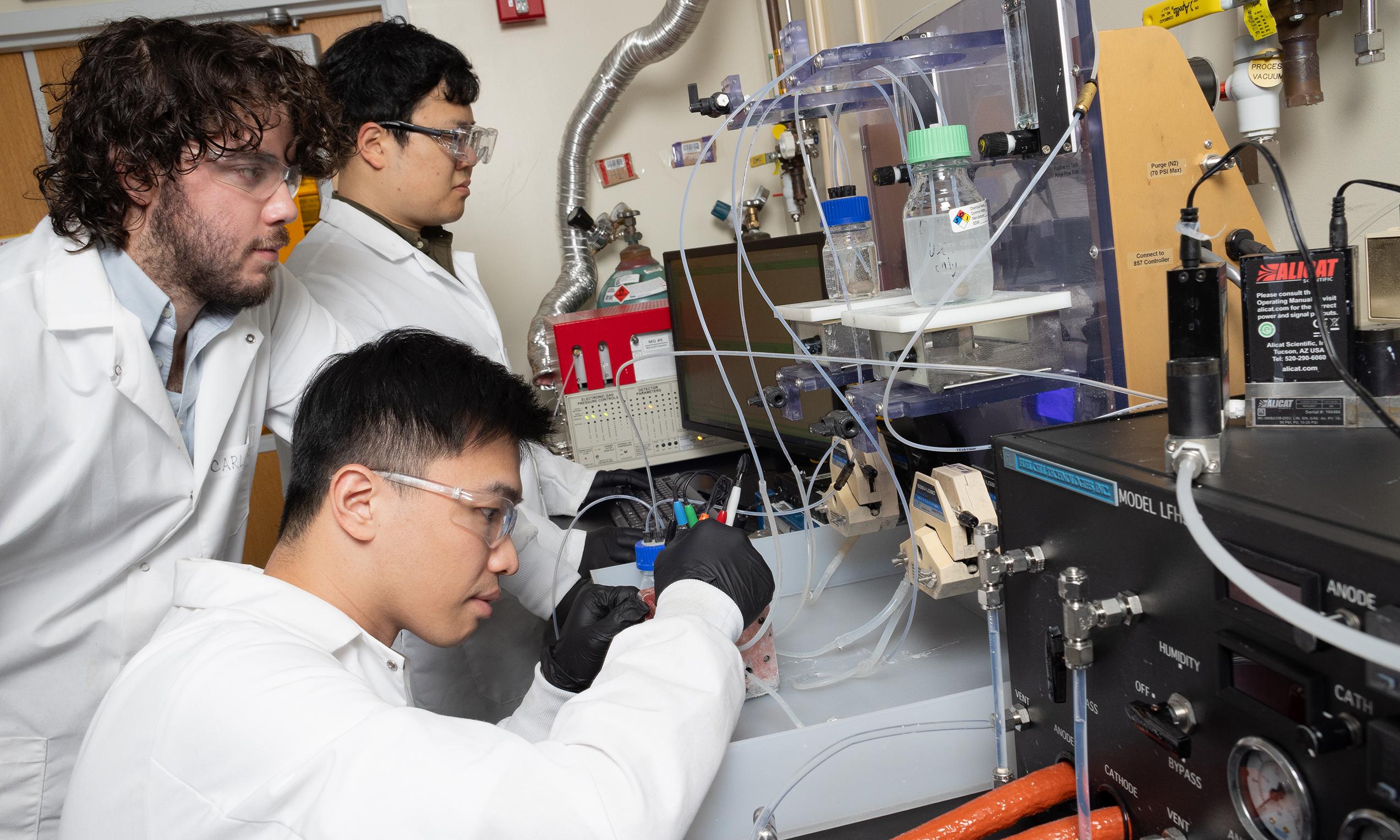

A new electrochemical reactor design developed with Marta Hatzell by postdoctoral scholar Hakhyeon Song (middle) and Ph.D. students Carlos Fernández and Po-Wei Huang (seated) converts carbon dioxide removed from the air into useful raw material. Their approach is cheaper and simpler while requiring less energy, making it a promising tool to improve the economics of direct air capture systems. (Photo: Candler Hobbs)

Engineers at Georgia Tech have designed a process that converts carbon dioxide removed from the air into useful raw material that could be used for new plastics, chemicals, or fuels.

Their approach dramatically reduces the cost and energy required for these direct air capture (DAC) systems, helping improve the economics of a process the researchers said will be critical to addressing climate change.

The key is a new kind of catalyst and electrochemical reactor design that can be easily integrated into existing DAC systems to produce useful carbon monoxide (CO) gas. It’s one of the most efficient such design ever described in scientific literature, according to lead researcher Marta Hatzell and her team. They published details April 16 in Energy and Environmental Science, a top journal for energy-related research.

Joshua Stewart

College of Engineering