Additive Manufacturing

Over the past decade, the Georgia Tech Manufacturing Institute (GTMI), along with the Georgia Tech Research Institute (GTRI) and GT faculty from multiple schools – Mechanical Engineering, Industrial and Systems Engineering, Aerospace Engineering, and Materials Science Engineering, have led major research initiatives in additive manufacturing (AM) and digital manufacturing, through Manufacturing USA Institutes and other government and industry sponsored research.

Georgia Tech's vision is to be a focal point for end-to-end systems integration of AM technologies, spanning product and materials design, process science, supply chain modeling, cybersecurity and industrial application development. In pursuit of this vision, the mission is to offer both external and internal stakeholders access to cutting edge research and software/hardware technologies for broad exploration of AM problems.

Major research initiatives in the area of AM include the following technical areas:

- Secure supply chain design

- Product design chain

- Process modeling/planning

- Rapid materials screening and property evaluation

- Secured automation

Secure Supply Chain Design

The goal of the secure supply chain design technical area is to support design and operations of data-driven AM supply chains with relocatable inventory, storage and/or manufacturing capacity that blend advantages of distributed systems (e.g., fast fulfillment) and centralized systems (e.g., scalability, risk pooling, less inventory, and reduced capital). This technical area focuses on exploring and defining new supply chain models for determining optimal configurations and hybrid approaches to the supply chain network, as well as identifying the impact of using AM for existing part designs to the overall supply chain network.

Product Design Chain

The goal of the product design chain area is to develop tools to guide practitioners through the various issues unique to AM for designing new products and identifying candidate legacy products. This technical area focuses on methods to generate design concepts such that the number of components is minimized, while ensuring manufacturability across the process chain.

Process Modeling/Planning

The goal of the process modeling/planning technical area is to realize capabilities for model-based AM process deployment, as well as process monitoring/control methods for born qualified production to support new part manufacture and repair development. This technical area focuses on establishing process monitoring capabilities for storing sensed data, investigating process-structure-properties relationships for various AM platform technologies and metal alloy systems, understanding superposed impact of downstream manufacturing processes (e.g., post processing).

Rapid Materials Screening and Property Evaluation

The goal of the rapid materials screening area is the rapid design, development, and implementation of autonomous workflows for rapid exploration and aggregation of data-driven knowledge systems capable of supporting cost-effective optimized materials-product design for AM multiscale multifunctional components. This technical area focuses on exploiting materials knowledge systems frameworks for rapid mapping of material structure and data rich process sensing information, establishing testbeds for rapid alloy screening, and supporting materials testing frameworks.

Secured Automation

The goal of the secured automation technical area is to develop process monitoring and control technologies and machine learning frameworks to support highly automated and secure production frameworks for AM systems. This technical area focuses on establishing persistent measurement testbeds for collecting data from AM machines during processing and data from downstream inspection equipment, as well as leveraging process/material model frameworks for qualifying builds from sensor data.

Georgia Tech is focused on aligning its capabilities to the pressing needs of its major research industry and government partners, including DoD and DOE – with respect to application areas, material classes, and process technologies. Recent projects have centered on material alloy development, repair process development, materials testing, applications testing and process modeling and have spanned multiple industries, including aerospace, automotive, biomanufacturing, defense and medicine.

Shared Use Facility and Equipment

The Applied Manufacturing Pilot Facility (AMPF), a unique shared use facility specifically designed for late stage translational research and education, houses much of GT’s additive manufacturing research and equipment.

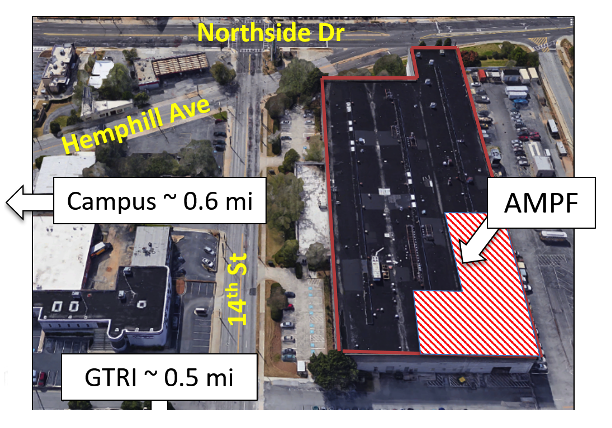

AMPF is a 20,000 square foot high bay located at the 14th Street GT facility. GTMI is charged by the Office of the EVPR with stewardship and operational responsibility for the AMPF, which serves as the “anchor facility” for development of a Manufacturing Innovation Neighborhood. AMPF was renovated through a foundation gift by Delta Airlines in 2017. AM capacity at GT is augmented with additional research facilities and equipment across campus.

AMPF at 14th Street

AMPF at 14th Street overhead view

Faculty and Research Collaborators at GT

Anne Clark, Ph.D., Chief Scientist/Sr. Research Engineer, GTRI

Suman Das, Ph.D., Morris M. Bryan, Jr. Chair in Mechanical Engineering for Advanced Manufacturing Systems and Professor

Surya Kalidindi, Ph.D., Regents Professor and Rae S. and Frank H. Neely Chair Professor in the Woodruff School of Mechanical Engineering

Shreyes Melkote, Ph.D., Morris M. Bryan, Jr. Professor in the Woodruff School of Mechanical Engineering

David Rosen, Ph.D., Professor, the Woodruff School of Mechanical Engineering

Chris Saldana, Ph.D., Ring Family Professor in Manufacturing

Chelsea White, Ph.D., Schneider National Chair in Transportation and Logistics and Professor in the H. Milton Stewart School of Industrial and Systems Engineering